W pełni automatyczny 6-zasypowy system dozowania, maszyna do dozowania nawozów

Jako wiodący producent sprzętu do nawozów, rozumiemy, że precyzyjne, wydajne i stabilne dozowanie jest podstawą wysokiej jakości produkcji nawozów. Niezależnie od tego, czy produkujesz nawóz organiczny, nawóz złożony, czy nawóz mieszany (nawóz BB), wydajność Twojej maszyny do dozowania bezpośrednio determinuje jakość i koszt Twojego produktu końcowego.

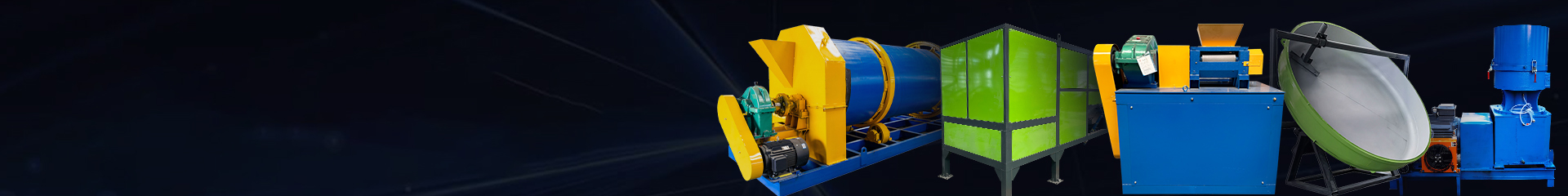

Przegląd produktu

Nasze maszyny do dozowania wykorzystują zaawansowaną technologię sterowania do precyzyjnego dozowania i dystrybucji różnych surowców używanych w produkcji nawozów, w tym azotu, fosforu, potasu, pierwiastków śladowych, wypełniaczy i dodatków. Bezproblemowo integrują się z mieszalnikami, młynkami i przenośnikami, tworząc zautomatyzowane linie produkcyjne, eliminując błędy ręcznego dozowania, nieefektywność i zanieczyszczenie pyłem.

Kluczowe cechy

Precyzyjne dozowanie: Dokładność ±0,5% zapewnia stabilną jakość nawozu

Automatyzacja i inteligencja: Sterowanie PLC z przechowywaniem i przywoływaniem receptur

Trwałość: Konstrukcja ze stali nierdzewnej/węglowej dla odporności na korozję

Elastyczna adaptacja: Obsługuje proporcje materiałów od 1:10+ dla różnych linii produkcyjnych

Ochrona środowiska: Zamknięte konstrukcje minimalizują rozlewanie się pyłu

Zastosowania

Linie produkcyjne nawozów złożonych

Linie produkcyjne nawozów organicznych

Produkcja nawozów mieszanych (nawóz BB)

Produkcja nawozów rozpuszczalnych w wodzie/specjalistycznych

Rodzaje produktów

| Typ |

Zasada działania |

Zalety |

Idealny dla |

| Dozownik statyczny |

Materiały ważone indywidualnie, gdy są nieruchome |

Najwyższa dokładność, szeroka kompatybilność materiałowa |

Wysokiej klasy nawozy złożone, rozpuszczalne w wodzie i organiczne |

| Dozownik dynamiczny |

Ciągłe ważenie podczas transportu materiału |

Wysoka wydajność, kompaktowa konstrukcja |

Produkcja nawozów BB i nawozów złożonych luzem |

Wskazówki dotyczące wyboru

Nasz zespół techniczny poleci optymalne rozwiązanie w oparciu o właściwości surowców, złożoność formuły, wymagania dotyczące wydajności produkcyjnej i budżet.

Gofine Machine zapewnia kompletne, dostosowane rozwiązania od projektu po uruchomienie, z głęboką wiedzą specjalistyczną w zakresie procesów produkcji nawozów.

Skontaktuj się z nami, aby uzyskać spersonalizowane rozwiązanie dostosowane do Twoich potrzeb produkcyjnych.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!